610 views Yuda Electronic (HK) Technology Co.,Limited. 2019-08-12

There are many types of power adapter housings, which are basically plastic and metal. For example, the electric lamp we use every day is a switching power supply case made of plastic. There are also transformers we use.

The power adapter housing basically has a relatively high temperature. This requires us to use some plastic switch power supply housings made of temperature-resistant materials. Generally speaking, the following materials are mainly used. Currently, there are several kinds of ABS, PC used in the transformer housing. , PC/ABS.

The first thing to explain is that the power adapter heating is a very normal phenomenon. How to calculate the working temperature of the power adapter housing? Today, the Yuda power adapter wholesale manufacturer explains for you:

The maximum operating temperature of the power adapter housing is carefully calculated and verified. The process for calculating the operating temperature of the power adapter housing is as follows.

(1) Determine the maximum output power required for the application.

(2) Determine the maximum operating ambient temperature of the application and use the highest ambient temperature around the power adapter.

(3) Determine the internal power consumption [Pinternal=P0Ut(l_q)/n].

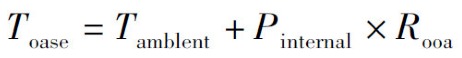

(4) Calculate the operating temperature of the power adapter housing:

Toase is the operating temperature of the enclosure; Tamblent is the ambient temperature; Pinternal is the internal power consumption; Rooa is the thermal impedance of the enclosure to the environment (Rooa=Roos+Rosa, Roos is the thermal impedance of the enclosure to the heat sink, R.^ is the heat sink to Thermal impedance of the environment).

Reduce the operating temperature of the power adapter housing

Under certain operating ambient temperature and output load conditions, the thermal impedance of the power adapter housing to the surrounding environment may cause the operating temperature of the enclosure to exceed a certain maximum. Therefore, it is necessary to reduce the thermal impedance of the outer casing to the surrounding environment, thereby reducing the operating temperature of the outer casing. The following techniques can be used to reduce the thermal impedance of the power adapter housing to the environment.

(1) Additional heat sink. The purpose of the heat sink is to increase the heat sink area to transfer heat from the power adapter to the air. This will result in less thermal impedance, but will increase the size of the power adapter.

(2) Provide airflow. Airflow can increase heat dissipation efficiency and reduce thermal impedance, which can force air to cool. The airflow reduces the thermal impedance without the need for a heat sink, and thus does not increase the size of the power adapter.

(3) For the high temperature of the outer casing, a thin aluminum foil can be laid inside the shell to achieve the purpose of heat dissipation.

(4) For the metal case, a heat sink can be added. The heat sink and the outer casing can be separate. After the package is completed, the heat sink and the outer casing are fixed by spring clips.

Cell phone accessories wholesale business can get high profits. But the market is fierce. Big bra...

Does fast charging reduce phone battery life? In order to allow everyone to understand this matt...

How to install the car charger: 1. Insert the USB power adapter into the car cigarette lig...